When constructing spiral silos, we employ spiral silo making machine throughout the entire process. As the outer wall of the silo takes shape, it forms a remarkable spiral rib measuring 28mm-50mm in width and five times the thickness of the coil material. This ingenious design significantly enhances the silo's load-bearing capacity, catapulting the overall strength and stability of our spiral silos above and beyond other storage systems.

What's more, we use corrosion-resistant and cost-effective galvanized steel coils, ensuring that our silos outlast other storage systems while also exhibiting exceptional resistance to vibrations.

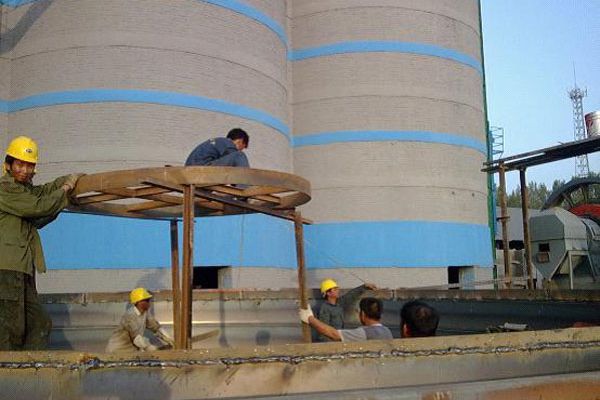

Step 1

Begin with a level ground and strategically plan the construction platform along the diameter line of the steel silo. Equip it with specialized spiral silo making machine, including double folding machine, forming machines, uncoiling unit, steel columns and supports etc.

Step 2

When the spiral has been processed with the second circle, we seamlessly stop the spiral silo manufacturing equipment and initiate the cutting process of the silo body's top horizontal line. Once the cutting is complete, we expertly weld the lower coil, positioning it snugly within the silo's central hub. Our engineers meticulously measure every detail using precision tools like level rulers and tape measures.

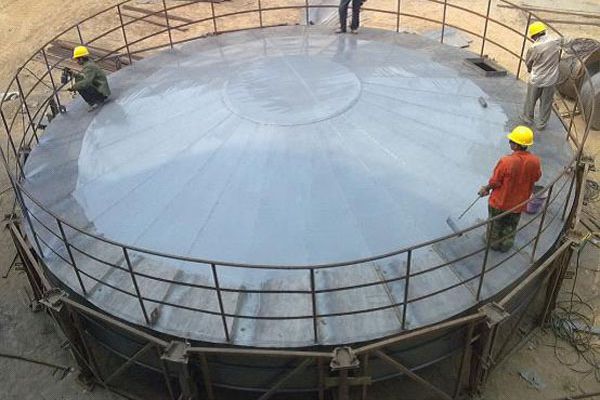

Step 3

Welding the roof purlin between the upper and lower coil

Step 4

Welding the silo roof panels

Step 5

Welding the silo roof panels, installing guardrails, and fitting the roof access hatch.

Step 6

Silo roof painting (this step is mainly applied to black steel plates).

Step 7

Continue operating the spiral silo making machine and continuously roll up. During this process, coordinate with paint spraying and, if necessary, pause for welding inside the silo to reinforce the ribs and install internal ladders.

Step 8

Reaching the predetermined design height, perform a horizontal cut at the bottom of the silo body, then use a crane to lift and place the silo onto the structural platform.

-

Silo Design Expertise

When it comes to designing and placing silos, meticulous attention to every component and accessory of the silo is crucial in creating an efficient bulk material storage and handling silo solutions. This encompasses factors like pile density, particle size, angle of repose, flowability, moisture content, corrosiveness, minimum ignition temperature, and more.

-

Construction Experience for Silo Solutions

Our professionals possess extensive practical experience in the design, manufacture, and installation of high-capacity silo solutions and associated industrial components and systems. Due to the intricate nature of these installations, our team must operate seamlessly to ensure the delivery of premium storage systems. Every stage of bulk material storage projects is critical to achieving the desired levels of performance and safety. Our seasoned engineering team meticulously crafts silo solutions with a focus on safety, reliability, and superior performance.