FAQs about Silo Machine

"Spiral folding technology" is originating from Germany and invented by the LIPP company. Our company has produced spiral silo making machine based on this technology, and various silo construction companies have purchased our spiral silo making machine to build thousands of storage tanks, spiral silos, and bins.

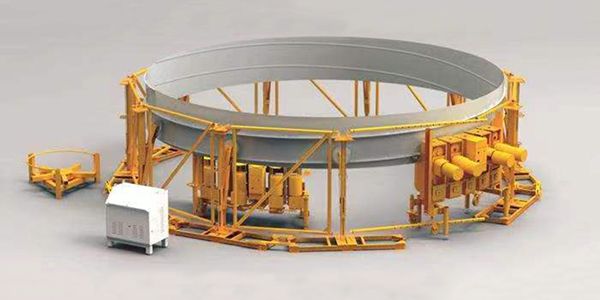

Our spiral silo machinery includes an uncoiling unit, silo steel strip forming machine, double folding machine, and load-bearing supporting unit.

Our silo equipment can accomplish stainless steel silo construction with diameters ranging from 3 to 8 meters, 6 to 22 meters, and 20 to 50 meters.

Our double folding machine can bend stainless steel sheets with thicknesses ranging from 1.5 to 3mm, 2 to 4mm, and 2 to 5mm.

Our primary customers have been silo construction companies involved in the construction of cement silos, grain silos, aggregate silos, cement silos, fly ash silos, gypsum powder storage silos, and more.

To date, our silo production machinery has been chosen by customers from dozens of countries, including Turkey, Italy, Brazil, Australia, South Africa, and many others, to build thousands of storage tanks, spiral silos, and bins.

Yes, when silo construction companies purchase our silo equipment, we arrange technical personnel to provide on-site guidance on how to use the equipment.

Yes, we provide different spare parts for various silo machinery. Please inquire with our after-sales service for more details!

FAQs about Silo Engineering and Construction Solutions

Due to our utilization of advanced spiral folding technology, we primarily specialize in complex spiral silo construction, such as flat-bottom spiral silos and hopper-bottom silos. Additionally, we can construct assembly silos and welded steel silos for simpler structural requirements.

As a professional silo construction company, we can identify the right silo system solution for power station plants, granular materials storage, and liquid storage tanks, among others, based on buyer requirements.

With our silo machines, we can construct silo systems in three size ranges: 3 to 8m in diameter, 6 to 22m in diameter, and 20 to 50m in diameter.

Our engineers will select the appropriate steel silo based on the silo's capacity and the type of products to be stored.

Yes, indeed. We have an efficient construction team, with most members having over six years of work experience.

Yes, if needed, we can provide paid installation or guidance services for silo storage systems. Alternatively, you can coordinate with local silo storage system contractors, and we can send a supervising engineer.

Yes, in addition to steel silo storage systems, we also provide auxiliary and supporting systems, such as loading and unloading systems, fluidizing discharge systems, as well as auxiliary equipment including bucket elevators, scraper conveyors, dust collectors, dryers, vibrating screens, and primary cleaning screens.

We are not only a supplier of silo machines but also have extensive experience in silo construction. Before starting silo construction, we carefully consider local weather conditions, humidity, and the location of the silo to implement various measures for rain and moisture protection.

We tailor the construction of silo plants to match local weather conditions, humidity, and the materials being stored. This approach permits a longer service life for our silos, which can typically last for 20 to 30 years.